there are lots and lots of carburetors out there....lots of differences...so i will condense the majority of the thread to info pertinent to my all time favorite 4-stroke carb... the KEIHIN FCR carb.... keihin is a subsidiary of Honda Motor Corp... and their 2-stroke and 4-stroke carbs are state of the art in performance....

they were the innovators that introduced a vacuum breaking plate slide design and also put the slide on rollers.... all this allowed for lower and lower spring pressure to reliably close a throttle on a 4-stroke.... big 4-strokes were notorious for having enough vacuum to draw and hold the slide stuck to the front of the slides bore.... against all but the heaviest of workable springs.... the more powerful the engine, the more the stuck wide open problem.... FCR changed all that....

also... for any aftermarket stuff i talk about here... you can hit up site sponsors :

KB Motorsports or Woodwards Specialties to get a killer deal on anything you decide you need....

it's going to take a while to complete.... but starting with something is the first step.... so here we go...

REMEMBER THAT STOCK IS WAY OFF when you start to mod your machine.... stock jetting is made for a restrictive closed off airbox and a terrible exhaust system... plus the factories tend to go lean anyways to help with emissions.... when you start modifying your machine by new exhaust and pulling your air box lid.... your jetting is going to be WAY OFF.... we will fix all of that by the time the thread is complete

gotta start at the beginning... so on with carb theory first... i'm going to use the word vaccuum here with some extra literary license.... pressure differential is really what i mean in a lot of cases....higher pressure in one area/ lower pressure in another causes a flow from high to low.... like the intake stroke of an engine opens a low pressure area and the higher pressure of the atmosphere outside rushes in to fill the cylinder in order to have equal pressures everywhere ...inside and out....

the carburetor is a decvice that works on pressure differentials in order to introduce an atomized / burnable amount of fuel into the air flow heading into your engine.... the finer the droplets can be "atomized" , the better the combustion will be.... big droplets only burn off the "skin" of the drop...the area that can easily react with available oxygen....

a carburetor has several different "fuel circuits".... meaning that there is a different circuit of the carb that is responsible for fuel flow depending on the amount of throttle opening....

these circuits all get fuel from the "float bowl" .... bottom of the carb....

called a float bowl because there are sealed air chamber "floats" that are responsible for keeping the bowl at steady level of fill.... they do this by pushing a valve closed when the gas lifts/floats them to the correct level... much like the back of a toilet could be called a float bowl...water rises and lifts a float until it actuates a valve to stop flow at the correct level....

now...once the gas is at the correct level in the bowl.... we can talk about the different percentages of throttle opening... and which jet circuit is primarily responsible for the fuel mixing at that opening...

FLOAT BOWL PIC

![Image]()

FLOAT ASSY AND NEEDLE VALVE THAT CONTROL FUEL FILL IN FLOAT BOWL

![Image]()

CLOSED THROTTLE:

throttle closed is when your fuel is controlled by the idle fuel screw... located at the bottom middle front of the carb.... affecting air fuel mixture at closed throttle / engine idling....

the fuel opening it feeds through is a very small one that you can see at the bottom of the bore on the engine side of the closed throttle slide... its straight up into the bore from the screw itself....

note :careful when adjusting it... dont ever close it too tight or you will damage the needle end or the seat...

all the way turned in is no fuel flow...and as you open the screw counter clockwise, you increase fuel flow...

on lots of machines the screw is an absolute beotch to get to... which makes it challenging to adjust while running.....

there are aftermarket fuel screw replacements that have heads you can use fingers to adjust (instead of screwdrivers) and numbers to read for reference positioning.... but all the ones i have seen have had the larger/ finger friendly head on them make them more prone to moving by vibration... and they like to vibrate loose and change adjustment... and in worst cases, they fall out...

but on my last go around, i decided to use the easiest to adjust ... as well as cant fall out style of idle fuel setup.... the RD Flex Jet... easiest way to adjust your idel fuel mix to perfection

if only all headaches could be fixed so easily...:clap

IDLE FUEL SCREW PIC

![Image]()

next up:

PILOT JET

the pilot jet is an short term intermediate circuit that takes over for a short time from completely closed throttle to about 1/8th to 1/4 throttle where the needle starts to dominate

you can think of it as responsible for the mix "just off idle".... and also a big part of fuel delivery when you have a "chopped throttle condition" higher rpms followed by a sharply closed throttle....

if you get a lot of popping at chopped throttle... your pilot is too small... you get one pulse going through being too lean for spark ignition... and the next pulse richens it up so it can light...but then that lights the lean mix that made it to the exhaust without the spark lighting it... pop..pop..pop

if your HEADPIPE GLOWS at idle, it will be either the idle fuel screw too lean...or the pilot too lean... or a combination of both.... 48~50 pilot is a common sweet spot for pilots jets...and 1.5 to 2.5 turns out from closed on the idle fuel screw is a common sweet spot

PILOT JET PIC... between main jet and idle fuel screw "down in the hole"

![Image]()

PILOT JET IS TOP LEFT IN THIS PIC

![Image]()

next up

NEEDLE JET

the needle has primary control over the fuel flow from approx 1/4th to 3/4ths throttle opening.... but it starts to come in at about 1/8th throttle...

the needle has different sections... first up is the base diameter...straight section of the needle that first gets exposed to the bore and vacuum when the throttle is just beginning to open.... the thichness the needle starts with is important for fuel flow at low opening and also for initiating flow ramp up when it hits the tapered section of the needle....

there are "clip positions" or grooves cut in the top of the needle that allows for the circlip that holds it in place to be moved up or down to change the part of throttle opening amount where the needle transitions from straight section to tapered section in the bore....

the tapered section of the needle being pulled farther and farther out of the main tube...allows for more and more fuel flow.....

the stock needle is made for the restrictive closed airbox and restrictive stock exhaust....

the first needle to go to when you start modding your yfz is the needle from its yz450f dirt bike brother... the NCVQ needle

I HAVE TO GET A BETTER PIC OF NEEDLE REMOVED FROM CARB... BUT THE FLAT BLACK ABOVE IT IS THE SLIDE/THROTTLE....NEEDLE IS THE THIN VERTICAL THING IN THE MIDDLE

![Image]()

GOT SOME BETTER PICS .... the center ring / venturi of the carb and a needle sitting in the position it travels through the center ring in.... needle taper is evident in that it gets thinner as it is pulled out farther (more fuel flow) ...and clip positions at top of needle to change the starting height of the needle.... clip near top is leaner ...clip near bottom is richer... not an fcr needle, but you get the idea

![Image]()

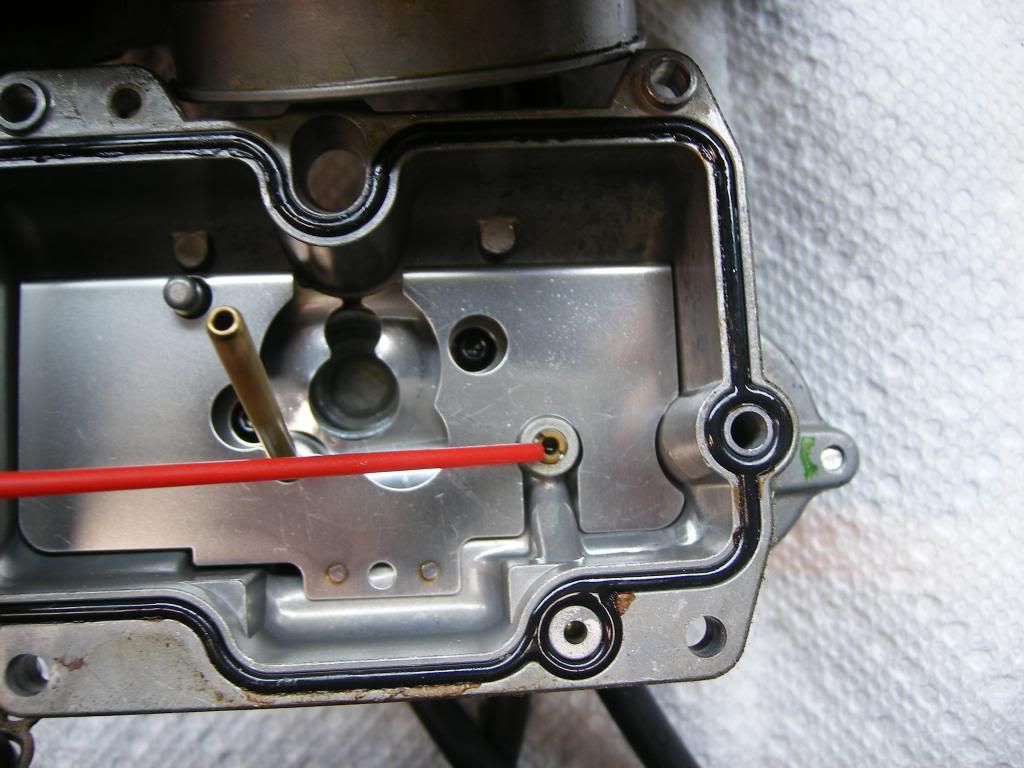

another pic of the center ring with the red pointer showing the orifice that the pilot jet feeds through into the carb bore.... when the slide is closed, there is significant amount of vacuum seen everywhere on the engine side of the slide.... in front of the idle jet orifice , in the carb body , is another tiny hole that the idle fuel screw feeds fuel to the carb bore though..

![Image]()

MAIN JET

the big daddy of the fuel meterers...lol... the bottom of the main tube that the needle rides is where the main jet lives.... once the tapered section of the needle is pulled out enough.... the bottom line of fuel delivery is the main jet at the bottom of the tube....

main jet is primarily responsible for fuel flow from 3/4 to W.O.T. (wide open throttle)

NOTE.... 4-strokes can be off by pretty big amount on jetting and still seem to run fine.... lean makes excess heat and can damage an engine ...rich dampens the burn AND washes oil off the cylinder walls... neither condition is good....

in dyno tuning i have seen rich conditions that seemed to run fine while riding, but have actually been keeping the machine down by as mch as 5 full hp at peak...... you can lose 5 hp and not know it by the way it runs... above that point in rich running you will notice a "false rev limiter" where the engine cuts out as though its on rev limiter... butits actually from being too rich....

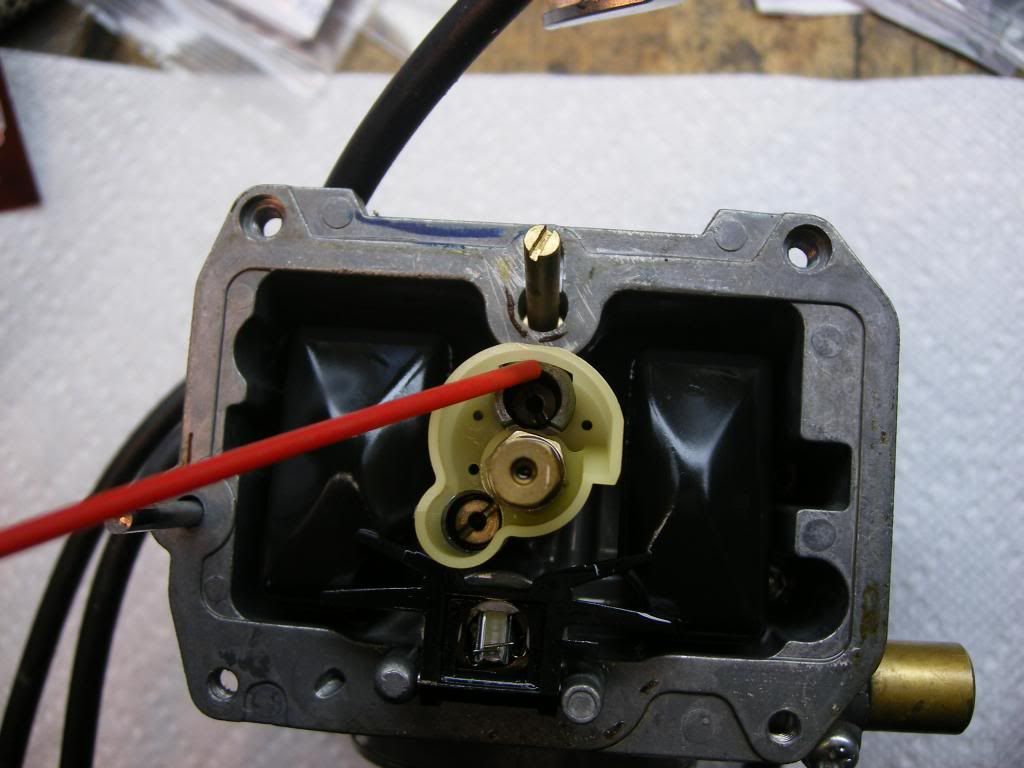

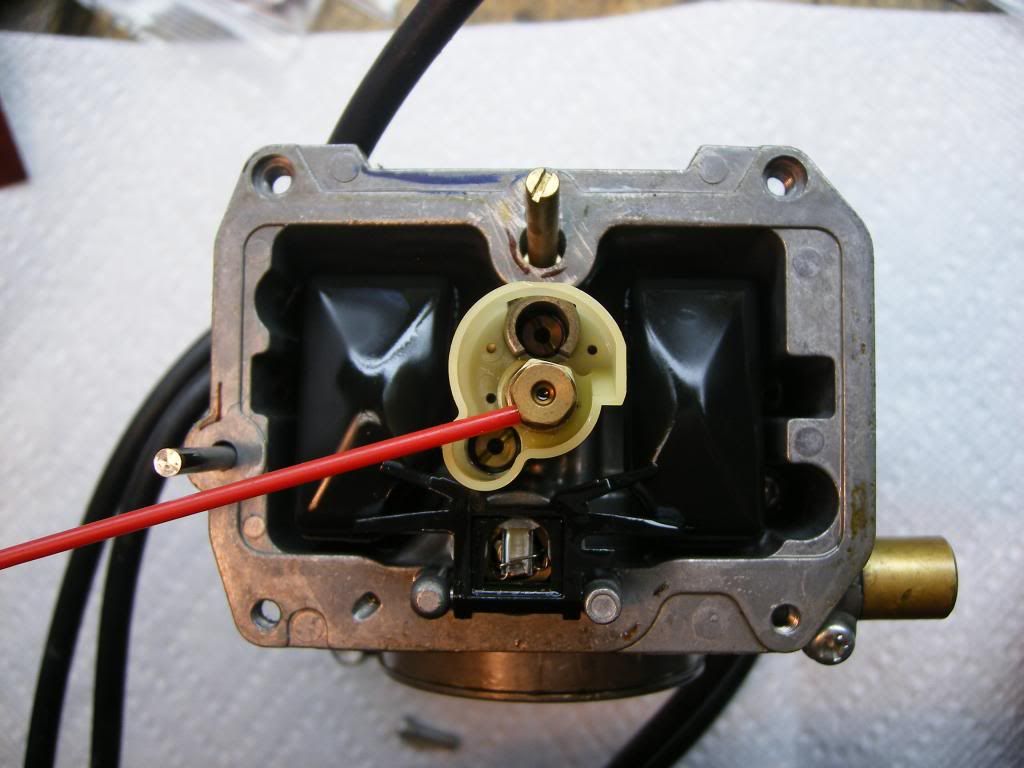

MAIN JET POSITION.... THE OFF WHITE PLASTIC THING COVERING THE JETS IS A SPLASH GUARD MEANT TO KEEP FUEL CONTAINED BY THE JETS OVER ROUGH TERRAIN

![Image]()

MAIN JET IS BOTTOM OF PIC...BELOW THE MAIN JET TUBE (NEEDLE PULLS IN AND OUT OF TUBE DURING OPERATION, WHEN NEEDLE IS PULLED ALL THE WAY UP, MAIN JET IS IN CONTROL OF FUEL)...ALSO SHOWN ARE PILOT JET AND JET SPLASH GUARD

![Image]()

MAIN JET CAP/ BOTTOM OF FLOAT BOWL / ACCESS TO MAIN JET.... IDLE FUEL SCREW AND MAIN JET ARE THE 2 YOU CAN SEMI EASILY WORK WITH WHILE THE CARB IS INSTALLED

![Image]()

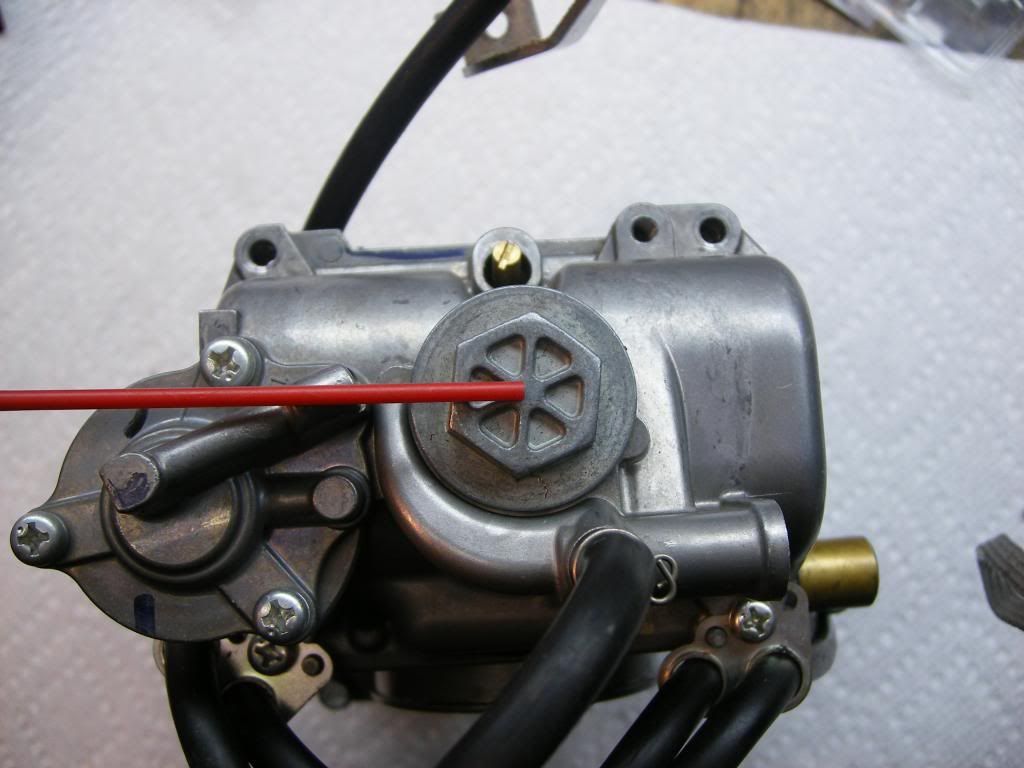

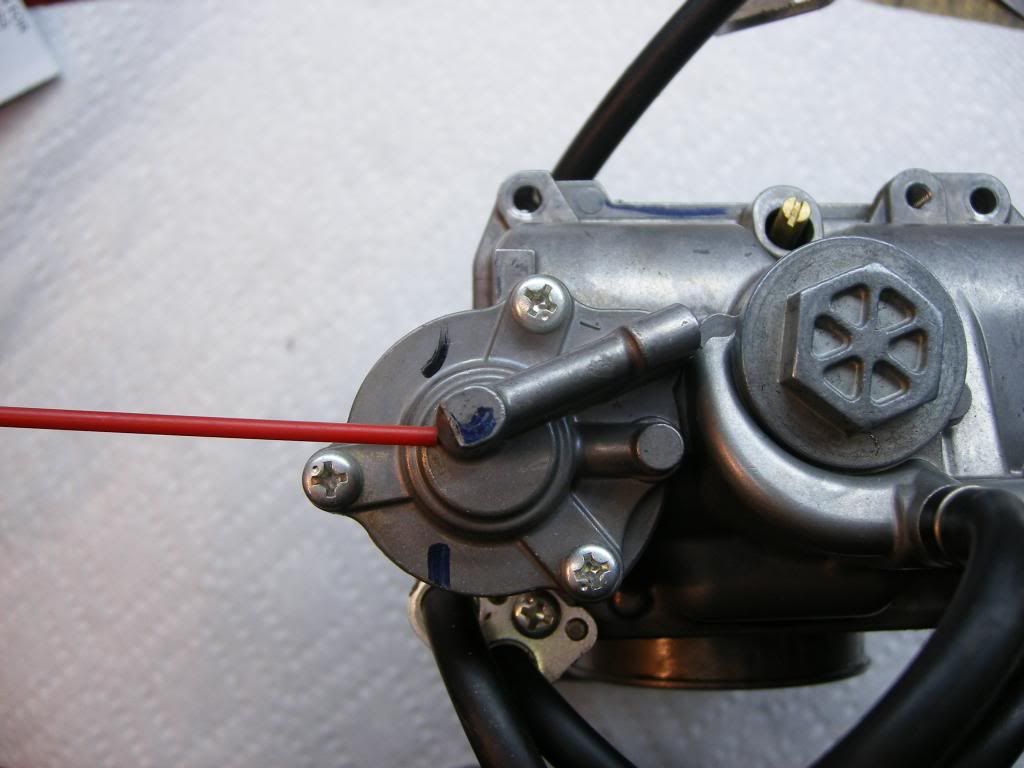

ACCELERATOR PUMP

great big HUGE deal on the fcr carbs....and another reason for them being the greatest carb for 4-stroke performance ... the accelerator pump...

as carbs get bigger and bigger for more top end performance... you will have a problem with throttle lag and bogging...even as extreme as the engine shutting off .... from a lean condition during large / fast throttle position opening changes....

the deal is that for each throttle position, you need a certain rpm range that creates the proper amount of airflow to create vacuum necessary to pull enough fuel through the desired circuit...

fast throttle openings means that the throttle is at a more open position before the engine rpm/vacuum has risen enough to pull fuel through it.... so a lean condition .... and bog can / will occur.... the bigger the carb to the size of the engine, the worse this problem would be....

the solution was made long ago on performance car carbs... like holley carbs.... single pumper and double pumper are common terms from the hot rodding community.... pumper means accelerator pump.... and what that is is a pump device on the carb that doesnt need vacuum to deliver fuel through it during big throttle stabbings....

the accelerator pump is like a small syringe setup that mechanically pumps a spray bottle like shot of fuel into the carb bore.... it is short term shot that provides the necessary fuel to cover the throttle position change until the engine rpm/ vacuum rises to the point it draws the appropriate amount of fuel through the appropriate carb circuit....

BOTTOM OF ACCELERATOR PUMP ASSY

![Image]()

ACCELERATOR PUMP NOZZLE / SHOOTS/DIRECTS PUMP SHOT THROUGH CARB BORE/ VENTURI.... STRAIGHT INTO INTAKE PORT

![Image]()

which brings us to another jet

LEAK JET

now that you know what the accelerator pump is... there is a jet associated with it... leak let... with different engine mods and setups, a different amount of accelerator pump shot will be needed to have sharp throttle response during fast/large throttle openings....

think of the accelerator pump like the syringe...and instead of the syringe having a needle on it , there is a small hose that goes from your syringe to the bore of the carburetor... the leak jet would be a changeable size jet that acts like a hole in the side of the hose...it determines how much of your pump shot will "leak out" of the hose , back into the float bowl, before it make it out the end of the hose into your carb bore....

pulling the airbox lid... more mods... bigger carb bore...bigger engine... all will need a smaller and smaller leak jet size to ensure less leak out and more of the shot is actually delivered.... in lots of cases for modified machines... a #35 to #40 leak jet end up being close to correct....

gotta pull the float bowl each tine to change this jet in the bottom of the bowl... when its right it right... but it can still be a pain to deal with...

RD and Boyesen both make accelerator pump caps (bottoms) that have an adjustable leak jet as part of them... i will cover the Boyesen QuickShot 3 in this article.... not necessary if you have the right leak jet... but what a pleasure to tune with.... sort of like "leak jets of the rich and famous" lol

LEAK JET LOCATED IN BOTTOM OF FLOAT BOWL / SMALLER JET = BIGGER PUMP SHOT

![Image]()

anyways guys..... i have SOOOOOOOO very much more to cover ...TONS of pictures.... and more tuning info than you want to think about...

but i will have to come back in and fill in all those blanks.... im going to make some place save posts so i can come back and fill stuff in in order

but at least i have started the 2-finger typing job from hell... baby steps

they were the innovators that introduced a vacuum breaking plate slide design and also put the slide on rollers.... all this allowed for lower and lower spring pressure to reliably close a throttle on a 4-stroke.... big 4-strokes were notorious for having enough vacuum to draw and hold the slide stuck to the front of the slides bore.... against all but the heaviest of workable springs.... the more powerful the engine, the more the stuck wide open problem.... FCR changed all that....

also... for any aftermarket stuff i talk about here... you can hit up site sponsors :

KB Motorsports or Woodwards Specialties to get a killer deal on anything you decide you need....

it's going to take a while to complete.... but starting with something is the first step.... so here we go...

REMEMBER THAT STOCK IS WAY OFF when you start to mod your machine.... stock jetting is made for a restrictive closed off airbox and a terrible exhaust system... plus the factories tend to go lean anyways to help with emissions.... when you start modifying your machine by new exhaust and pulling your air box lid.... your jetting is going to be WAY OFF.... we will fix all of that by the time the thread is complete

gotta start at the beginning... so on with carb theory first... i'm going to use the word vaccuum here with some extra literary license.... pressure differential is really what i mean in a lot of cases....higher pressure in one area/ lower pressure in another causes a flow from high to low.... like the intake stroke of an engine opens a low pressure area and the higher pressure of the atmosphere outside rushes in to fill the cylinder in order to have equal pressures everywhere ...inside and out....

the carburetor is a decvice that works on pressure differentials in order to introduce an atomized / burnable amount of fuel into the air flow heading into your engine.... the finer the droplets can be "atomized" , the better the combustion will be.... big droplets only burn off the "skin" of the drop...the area that can easily react with available oxygen....

a carburetor has several different "fuel circuits".... meaning that there is a different circuit of the carb that is responsible for fuel flow depending on the amount of throttle opening....

these circuits all get fuel from the "float bowl" .... bottom of the carb....

called a float bowl because there are sealed air chamber "floats" that are responsible for keeping the bowl at steady level of fill.... they do this by pushing a valve closed when the gas lifts/floats them to the correct level... much like the back of a toilet could be called a float bowl...water rises and lifts a float until it actuates a valve to stop flow at the correct level....

now...once the gas is at the correct level in the bowl.... we can talk about the different percentages of throttle opening... and which jet circuit is primarily responsible for the fuel mixing at that opening...

FLOAT BOWL PIC

FLOAT ASSY AND NEEDLE VALVE THAT CONTROL FUEL FILL IN FLOAT BOWL

CLOSED THROTTLE:

throttle closed is when your fuel is controlled by the idle fuel screw... located at the bottom middle front of the carb.... affecting air fuel mixture at closed throttle / engine idling....

the fuel opening it feeds through is a very small one that you can see at the bottom of the bore on the engine side of the closed throttle slide... its straight up into the bore from the screw itself....

note :careful when adjusting it... dont ever close it too tight or you will damage the needle end or the seat...

all the way turned in is no fuel flow...and as you open the screw counter clockwise, you increase fuel flow...

on lots of machines the screw is an absolute beotch to get to... which makes it challenging to adjust while running.....

there are aftermarket fuel screw replacements that have heads you can use fingers to adjust (instead of screwdrivers) and numbers to read for reference positioning.... but all the ones i have seen have had the larger/ finger friendly head on them make them more prone to moving by vibration... and they like to vibrate loose and change adjustment... and in worst cases, they fall out...

but on my last go around, i decided to use the easiest to adjust ... as well as cant fall out style of idle fuel setup.... the RD Flex Jet... easiest way to adjust your idel fuel mix to perfection

if only all headaches could be fixed so easily...:clap

IDLE FUEL SCREW PIC

next up:

PILOT JET

the pilot jet is an short term intermediate circuit that takes over for a short time from completely closed throttle to about 1/8th to 1/4 throttle where the needle starts to dominate

you can think of it as responsible for the mix "just off idle".... and also a big part of fuel delivery when you have a "chopped throttle condition" higher rpms followed by a sharply closed throttle....

if you get a lot of popping at chopped throttle... your pilot is too small... you get one pulse going through being too lean for spark ignition... and the next pulse richens it up so it can light...but then that lights the lean mix that made it to the exhaust without the spark lighting it... pop..pop..pop

if your HEADPIPE GLOWS at idle, it will be either the idle fuel screw too lean...or the pilot too lean... or a combination of both.... 48~50 pilot is a common sweet spot for pilots jets...and 1.5 to 2.5 turns out from closed on the idle fuel screw is a common sweet spot

PILOT JET PIC... between main jet and idle fuel screw "down in the hole"

PILOT JET IS TOP LEFT IN THIS PIC

next up

NEEDLE JET

the needle has primary control over the fuel flow from approx 1/4th to 3/4ths throttle opening.... but it starts to come in at about 1/8th throttle...

the needle has different sections... first up is the base diameter...straight section of the needle that first gets exposed to the bore and vacuum when the throttle is just beginning to open.... the thichness the needle starts with is important for fuel flow at low opening and also for initiating flow ramp up when it hits the tapered section of the needle....

there are "clip positions" or grooves cut in the top of the needle that allows for the circlip that holds it in place to be moved up or down to change the part of throttle opening amount where the needle transitions from straight section to tapered section in the bore....

the tapered section of the needle being pulled farther and farther out of the main tube...allows for more and more fuel flow.....

the stock needle is made for the restrictive closed airbox and restrictive stock exhaust....

the first needle to go to when you start modding your yfz is the needle from its yz450f dirt bike brother... the NCVQ needle

I HAVE TO GET A BETTER PIC OF NEEDLE REMOVED FROM CARB... BUT THE FLAT BLACK ABOVE IT IS THE SLIDE/THROTTLE....NEEDLE IS THE THIN VERTICAL THING IN THE MIDDLE

GOT SOME BETTER PICS .... the center ring / venturi of the carb and a needle sitting in the position it travels through the center ring in.... needle taper is evident in that it gets thinner as it is pulled out farther (more fuel flow) ...and clip positions at top of needle to change the starting height of the needle.... clip near top is leaner ...clip near bottom is richer... not an fcr needle, but you get the idea

another pic of the center ring with the red pointer showing the orifice that the pilot jet feeds through into the carb bore.... when the slide is closed, there is significant amount of vacuum seen everywhere on the engine side of the slide.... in front of the idle jet orifice , in the carb body , is another tiny hole that the idle fuel screw feeds fuel to the carb bore though..

MAIN JET

the big daddy of the fuel meterers...lol... the bottom of the main tube that the needle rides is where the main jet lives.... once the tapered section of the needle is pulled out enough.... the bottom line of fuel delivery is the main jet at the bottom of the tube....

main jet is primarily responsible for fuel flow from 3/4 to W.O.T. (wide open throttle)

NOTE.... 4-strokes can be off by pretty big amount on jetting and still seem to run fine.... lean makes excess heat and can damage an engine ...rich dampens the burn AND washes oil off the cylinder walls... neither condition is good....

in dyno tuning i have seen rich conditions that seemed to run fine while riding, but have actually been keeping the machine down by as mch as 5 full hp at peak...... you can lose 5 hp and not know it by the way it runs... above that point in rich running you will notice a "false rev limiter" where the engine cuts out as though its on rev limiter... butits actually from being too rich....

MAIN JET POSITION.... THE OFF WHITE PLASTIC THING COVERING THE JETS IS A SPLASH GUARD MEANT TO KEEP FUEL CONTAINED BY THE JETS OVER ROUGH TERRAIN

MAIN JET IS BOTTOM OF PIC...BELOW THE MAIN JET TUBE (NEEDLE PULLS IN AND OUT OF TUBE DURING OPERATION, WHEN NEEDLE IS PULLED ALL THE WAY UP, MAIN JET IS IN CONTROL OF FUEL)...ALSO SHOWN ARE PILOT JET AND JET SPLASH GUARD

MAIN JET CAP/ BOTTOM OF FLOAT BOWL / ACCESS TO MAIN JET.... IDLE FUEL SCREW AND MAIN JET ARE THE 2 YOU CAN SEMI EASILY WORK WITH WHILE THE CARB IS INSTALLED

ACCELERATOR PUMP

great big HUGE deal on the fcr carbs....and another reason for them being the greatest carb for 4-stroke performance ... the accelerator pump...

as carbs get bigger and bigger for more top end performance... you will have a problem with throttle lag and bogging...even as extreme as the engine shutting off .... from a lean condition during large / fast throttle position opening changes....

the deal is that for each throttle position, you need a certain rpm range that creates the proper amount of airflow to create vacuum necessary to pull enough fuel through the desired circuit...

fast throttle openings means that the throttle is at a more open position before the engine rpm/vacuum has risen enough to pull fuel through it.... so a lean condition .... and bog can / will occur.... the bigger the carb to the size of the engine, the worse this problem would be....

the solution was made long ago on performance car carbs... like holley carbs.... single pumper and double pumper are common terms from the hot rodding community.... pumper means accelerator pump.... and what that is is a pump device on the carb that doesnt need vacuum to deliver fuel through it during big throttle stabbings....

the accelerator pump is like a small syringe setup that mechanically pumps a spray bottle like shot of fuel into the carb bore.... it is short term shot that provides the necessary fuel to cover the throttle position change until the engine rpm/ vacuum rises to the point it draws the appropriate amount of fuel through the appropriate carb circuit....

BOTTOM OF ACCELERATOR PUMP ASSY

ACCELERATOR PUMP NOZZLE / SHOOTS/DIRECTS PUMP SHOT THROUGH CARB BORE/ VENTURI.... STRAIGHT INTO INTAKE PORT

which brings us to another jet

LEAK JET

now that you know what the accelerator pump is... there is a jet associated with it... leak let... with different engine mods and setups, a different amount of accelerator pump shot will be needed to have sharp throttle response during fast/large throttle openings....

think of the accelerator pump like the syringe...and instead of the syringe having a needle on it , there is a small hose that goes from your syringe to the bore of the carburetor... the leak jet would be a changeable size jet that acts like a hole in the side of the hose...it determines how much of your pump shot will "leak out" of the hose , back into the float bowl, before it make it out the end of the hose into your carb bore....

pulling the airbox lid... more mods... bigger carb bore...bigger engine... all will need a smaller and smaller leak jet size to ensure less leak out and more of the shot is actually delivered.... in lots of cases for modified machines... a #35 to #40 leak jet end up being close to correct....

gotta pull the float bowl each tine to change this jet in the bottom of the bowl... when its right it right... but it can still be a pain to deal with...

RD and Boyesen both make accelerator pump caps (bottoms) that have an adjustable leak jet as part of them... i will cover the Boyesen QuickShot 3 in this article.... not necessary if you have the right leak jet... but what a pleasure to tune with.... sort of like "leak jets of the rich and famous" lol

LEAK JET LOCATED IN BOTTOM OF FLOAT BOWL / SMALLER JET = BIGGER PUMP SHOT

anyways guys..... i have SOOOOOOOO very much more to cover ...TONS of pictures.... and more tuning info than you want to think about...

but i will have to come back in and fill in all those blanks.... im going to make some place save posts so i can come back and fill stuff in in order

but at least i have started the 2-finger typing job from hell... baby steps